What is a vaporizer?

What we do at CEPHI?

The different types of vaporizers

Sprayers with tray

These vaporizers consist of a tubular bundle in which the gas flows. The beam is immersed in a tank containing water. The gas in the liquid phase at the beginning, will draw calories on the walls of the tube as it progresses inside the beam. The beam cooled by the calories taken by the gas will cool in turn and draw calories in the fluid that surrounds it.

If we do not bring calories to the fluid contained in the tank and surrounds the beam then this fluid will cool until going into solid phase (ice). This is a stopping point for the proper operation of the vaporizer.

To bring calories we can use:

- steam so as to regulate the temperature of the tank,

- hot water from a boiler running on fuel or gas,

- one or more electric resistances that will heat the water,

- city gas that through an autonomous system (T.I.C.) will regulate the temperature of the water tank,

- process water when the end user has it,

- groundwater.

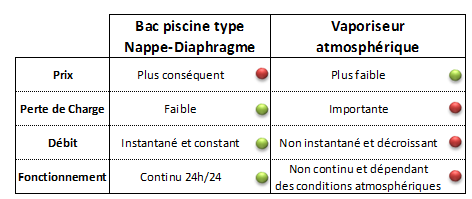

Each of these possibilities has its advantages and disadvantages, as shown in the table below.

Advantages and disadvantages of the different calorific inputs of vaporizers

Description of the beam

It is a pressure vessel that contains:

- gas in the liquid phase,

- on a certain portion of the two-phase gas beam, that is, a gas mixture in liquid and gaseous phase,

- gas phase gas.

We offer all kinds of beams. The parameters that intervene and which guide the choice of design are:

- the permissible pressure loss by the customer, namely, the pressure difference between the outlet of the vaporizer and the inlet thereof,

- the linearity and the reactivity in the vaporization, in other words, the dynamism of the vaporizer,

- the non acceptance of water hammer on start-up.

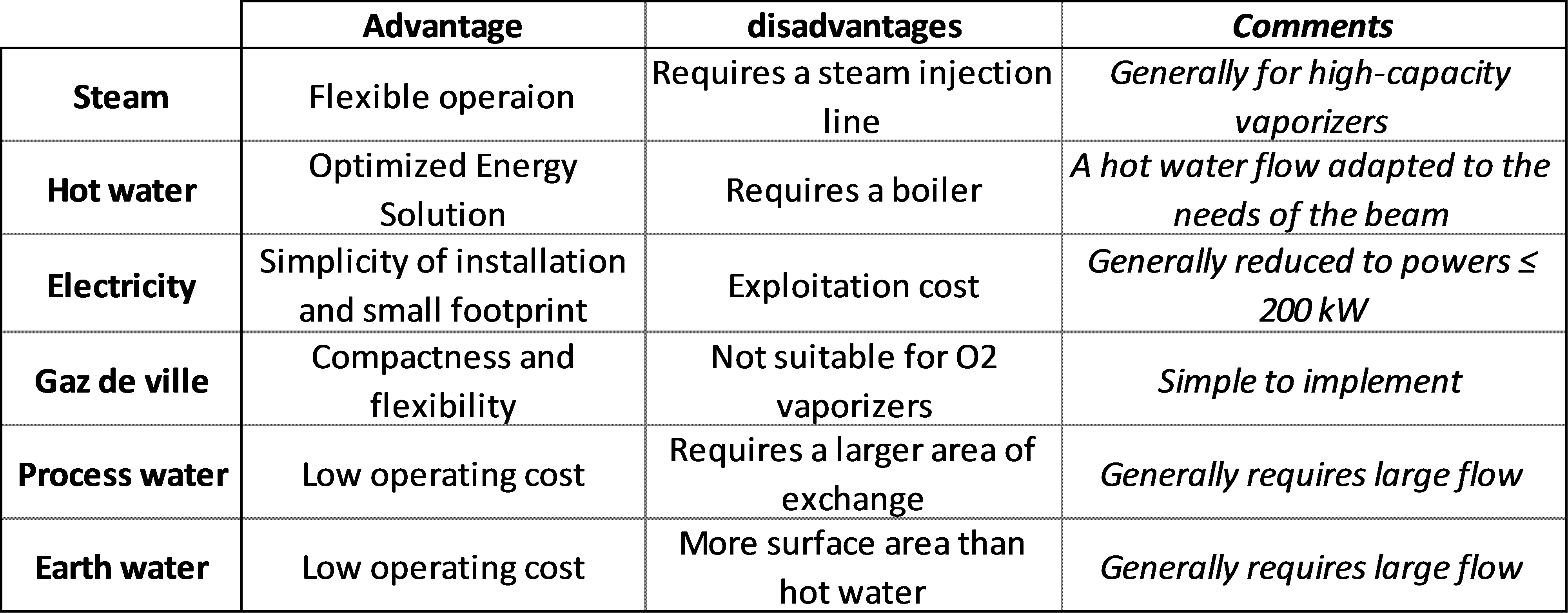

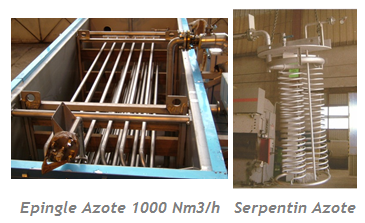

In the case where the permissible loss of load is important, we can propose a serpentine or hairpin tubular bundle.

On the other hand, if the customer wants to have high performances with an instantaneous and linear flow, minimal pressure losses and overcome the water hammers, another equipment is necessary: The nappe diaphragm® CEPHI.

The nappe diaphragm’CEPHI

Outstanding performance for the most critical applications

Considerable advantages over conventional systems:

- The nappe diaphragm® minimizes pressure losses with a DP <300 mbar,

- The nappe diaphragm® guarantees instant, consistent and constant flow,

- The nappe diaphragm® eliminates water hammers thanks to its exclusive design. It therefore ensures exceptional longevity of the equipment,

- The nappe diaphragm® is suitable for ALL flow rates.

ICT warming

Combining high performance, respect for the environment and safety

This system, associated with the nappe diaphragm bundle, offers major economic, technical and environmental benefits:

- Strong performance of the ICT system

- Very limited floor space

- Device autonomy

- Precise maintenance of the water temperature of the tank to within a few degrees C of the set temperature

- Nominal flow rate of instant flash fluid Elimination of the risks of liquid gas plugs and pulsations

- Reduction of losses: the flue gas outlet temperature is 110 ° C instead of 140 to 180 ° C with a conventional boiler

- Respect for European environmental standards

- No risk of pollution of the bath water: the combustion product of the gas burner circulates independently in the TIC immersion heat exchanger and is not in direct contact with the bath water

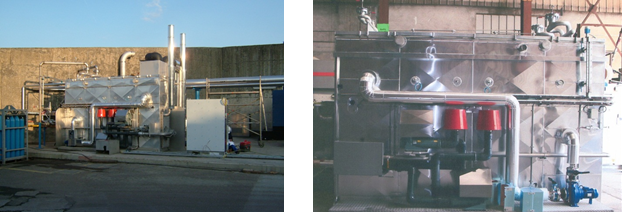

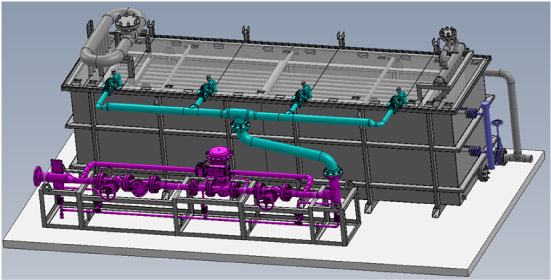

Argon vaporizer 2 * 6 350 Nm3 / h Double T.I.C Diaphragm tablecloth

Nitrogen Vaporizers ICT Nitrogen Vaporizers 32,000 Nm3 / h 80 bar 16,000 Nm3 / h 40 bar

Atmospheric heaters

These high or low pressure heaters draw from the ambient atmosphere, the energy necessary for the vaporization of cryogenic liquids. They are therefore characterized by their external exchange surface which is particularly important.

On the other hand, their vaporization rate varies according to the atmospheric conditions and the continuous operating time. As an indication, the variation in the case of continuous operation can be reduced by 50% over a period of 12 hours. Between an ambient temperature of -10 ° C and + 25 ° C the flow will vary from ~ 50%. This explains why this type of device is reserved for discontinuous needs.

Cryoptim

For the OPTIMization of your CRYOgenic systems.

Energy is more and more expensive. In terms of gas vaporization, the annual energy operating cost is a multiple of the cost of purchasing the vaporizer itself.

The interest of having a cryogenic installation optimized from an energy point of view has an undeniable economic interest.

With CRYOPTIM®, be sure to have a CRYOgenic OPTIMum installation for your operation.

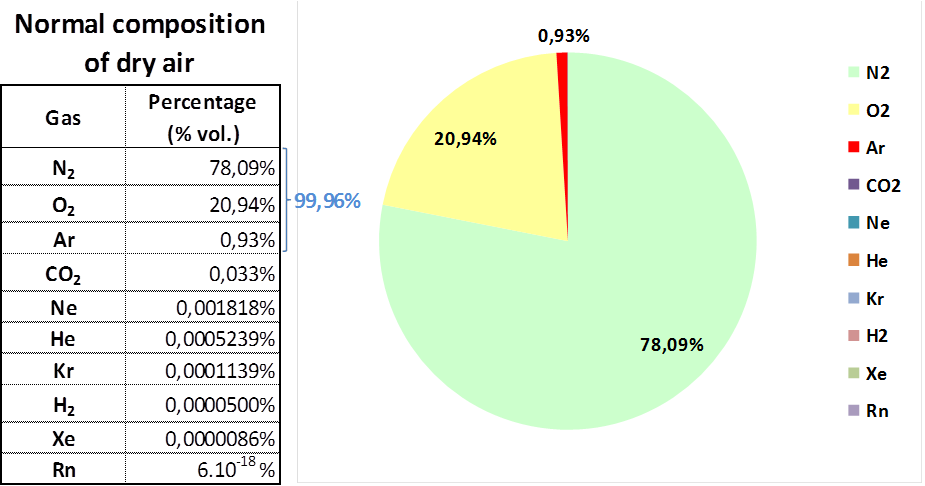

The air that constitutes the Earth’s atmosphere is a gas mixture, transparent, odorless, tasteless, of relatively constant concentration: only the concentrations of water and carbon dioxide can vary.

The gases opposite are extracted from the air. As the density is very low in the gas phase and at atmospheric pressure, they are stored at high pressures (generally 20 or 30 bar) and at very cold temperatures <-180 ° C.

Compressing and cooling the gas reduces its volume in ratios between 700 and 900 times relative to atmospheric pressure and ambient temperature to 20 ° C.

Subsequently, to be used, the gas stored in the liquid phase must be converted back into the gas phase.